highlights

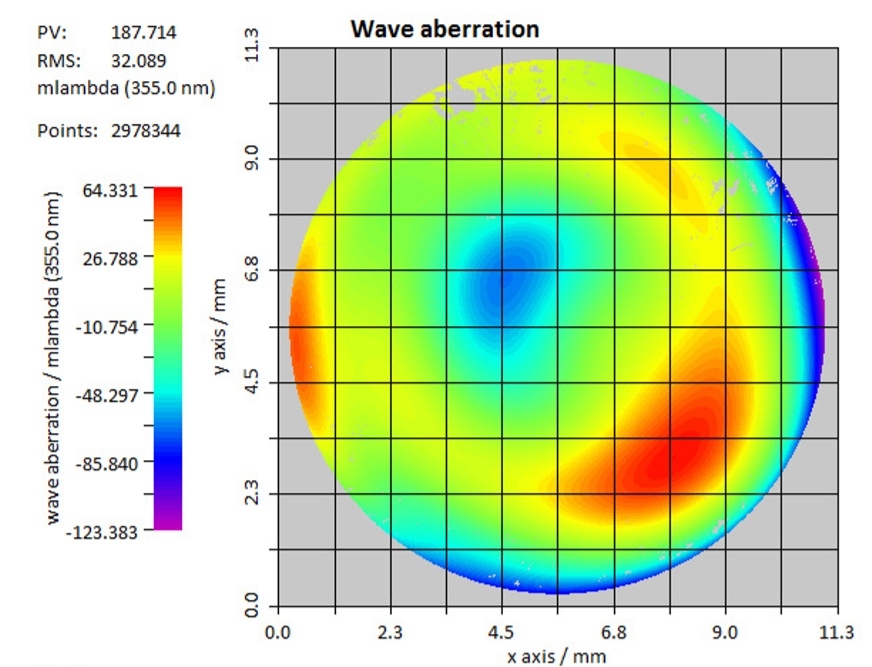

- Customized interferometric double pass wave front analysis

- Distortion measurement < 100 nm

- Field curvature

- MTF values using various targets/grids

- Through focus scans

- Telecentricity

objective qualification.

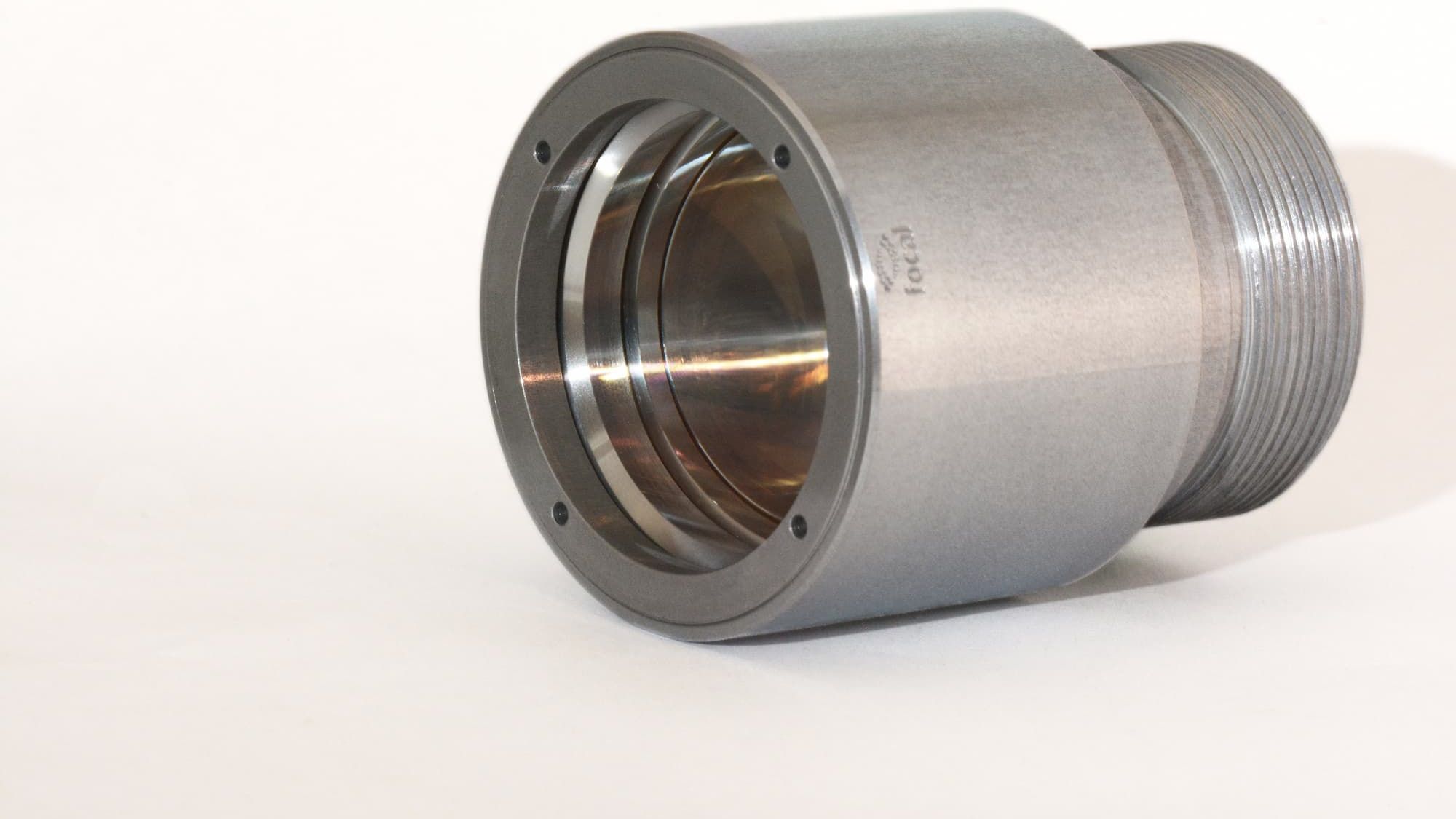

In the UV focus objective project, we developed a UV-interferometric double pass wavefront analyzer. That was capable of measuring distortion less than 100 nanometers. We were able to measure the field curvature, MTF values using various targets and grids and telecentricity.

.jpg)

"from start to end."

When design and reality come together in a lens assembly, it is vitally important to validate the reality to that design. For me, this is one of the most interesting parts of the project. It provides the opportunity to observe the actual result of the project. Furthermore, measuring through some fairly complex parameters of an optical design has some beauty in itself. At Demcon focal, we have the expertise to deliver the full package.