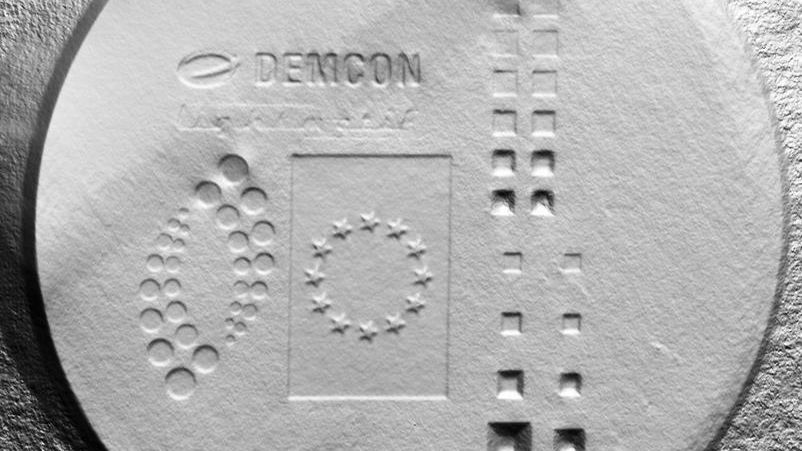

How to create a laser-ablation production system capable of zero-defect production? With this challenge, Demcon focal engaged in the Adalam project. Within this project, Demcon focal was responsible for in-situ measuring of the surface profile through the same f-theta lens as the high-power ablation laser.

We developed a depth sensor that uses the optical interference effect of broadband light between a reference path and signal path to derive the optical path length difference between these two branches.

The calculation of the Fourier transformation of the acquired spectrum provides a spectral intensity as function of the depth. For each scanned position, an intensity peak is derived at the distance which represents the depth of the sample.

To overcome aberration because the micro milling system was optimized for one wavelength, we investigated the possibility of using adaptive optics to optimize the sensor.

highlights

- Measurement depth range: 1.2mm

- Lateral resolution: 20 µm

- Repeatability: 1.5 µm

- Max. Meas. Rate: 20 kHz

- Max. FOV: 20 x 20 mm

integration.

The depth sensor was successfully integrated into a laser micromachining system. This new sensor allows the machine to get feedback on the actual machined depth, which is used to automatically adapt the micromachining process. This process results in an increased depth accuracy of the machined structures.

"faster, simpler, more accurate."

The result of this project showed that is possible to bring offline measurements into a machine.