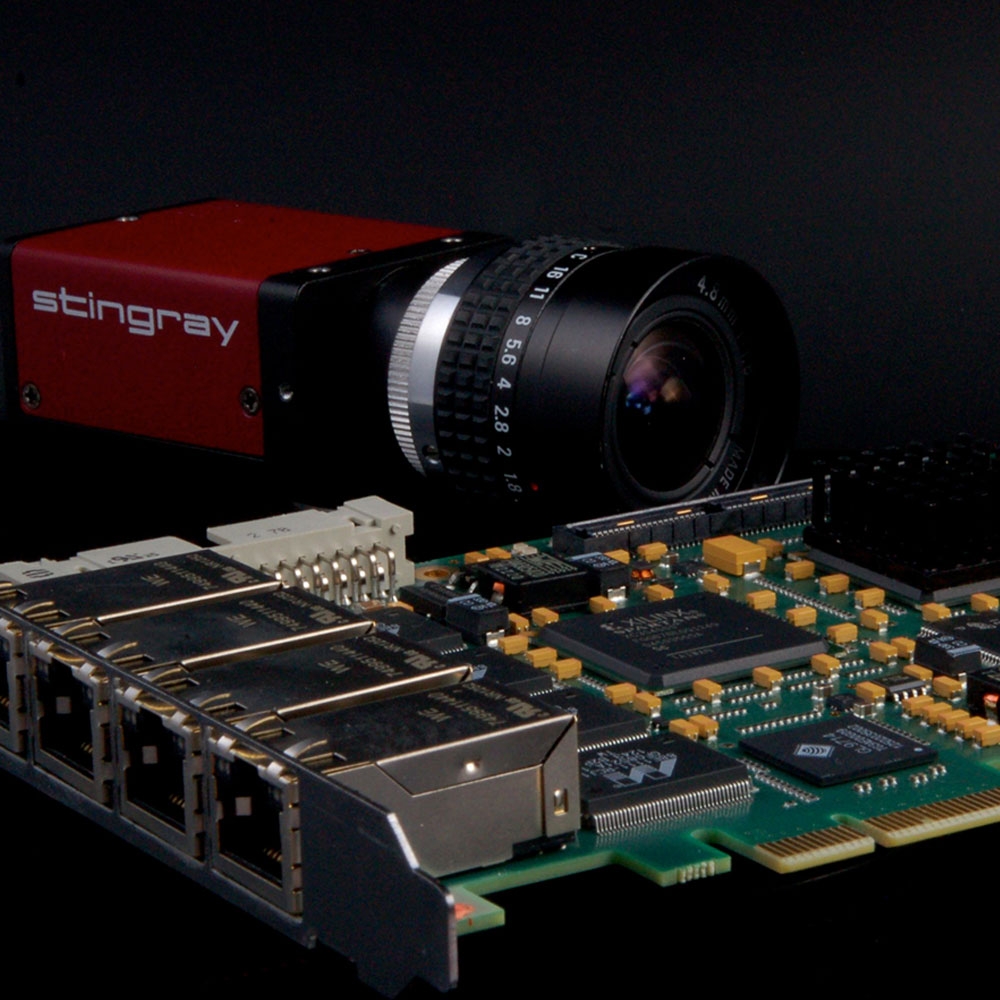

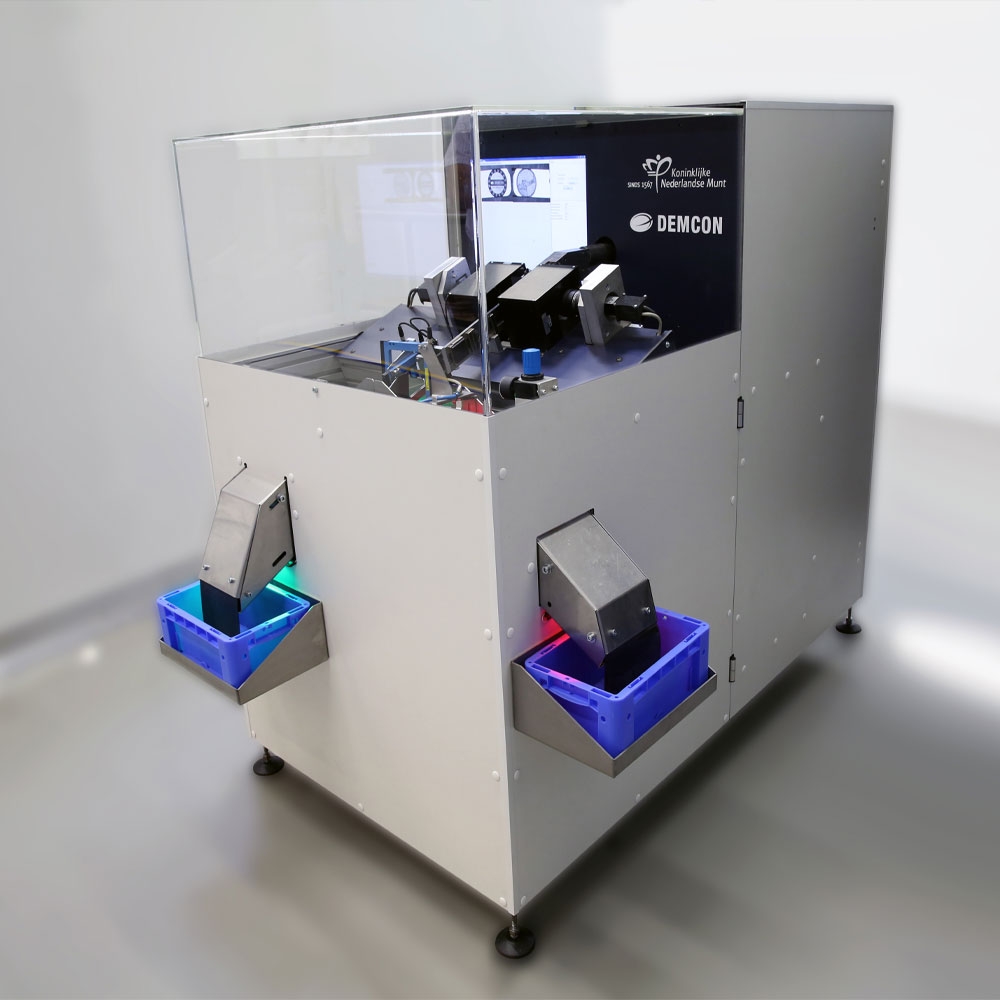

vision-in-the-loop.

As camera frame rates increase, true real-time vision-controlled systems will become cost-effectively available. Visual inspection loops of 2D image computing at 1,000Hz will be reality. We design and implement FPGA-based vision-in-the-loop solutions for real-time, precision quality inspection in a control & feedback loop.

optics manufacturing.

Creating state-of-the-art custom optics involves close collaboration between optical, opto-mechanical, and mechanical engineering disciplines to design a lens system that meets its requirements. Intimate knowledge of assembly equipment and its possibilities are needed to realize a prototype. Demcon focal has the facilities and practical assembly experience to deliver the customer’s lens system. For various customers Demcon focal has assembled and aligned optics, such as:

• F-theta lens with a long working distance

• Focusing lens with a Strehl ratio > 0.95

• Lens systems for various microscopic applications

• Lenses for lighting applications

• Lithography lens with a distortion < 100 nm

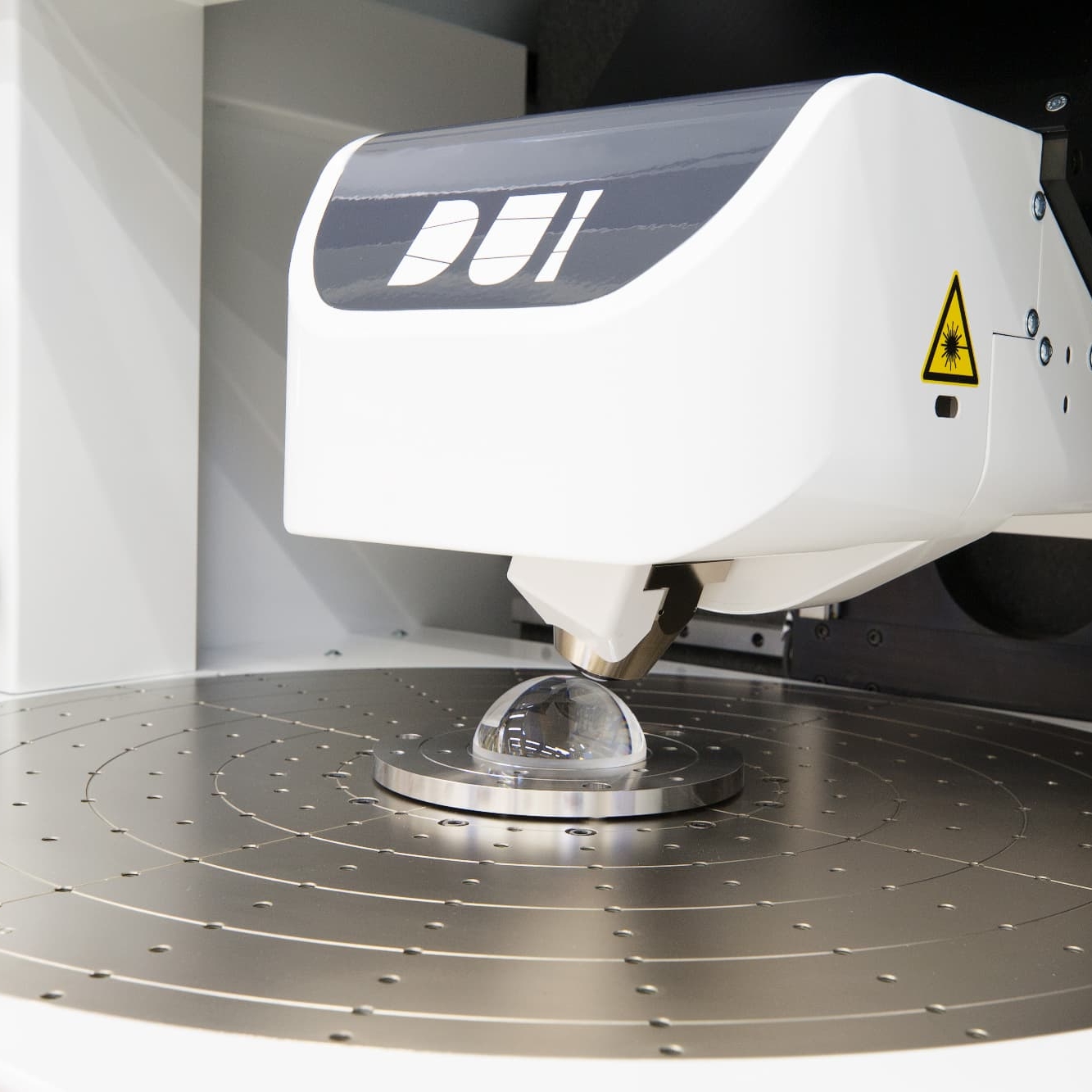

freeform optical components.

Modelling, manufacturing, and measuring freeform optics is maturing. Cost-effective aspheres, rotational invariant discontinuous surfaces, structured surfaces, arrays of lenses or pyramids can be introduced in optical systems. This allows optical engineers more design freedom in areas such as semiconductor development, consumer electronics (HMD, mobile phone cameras, etc.), general lighting and automotive applications (LED) and medical e.g., personalized ophthalmology.

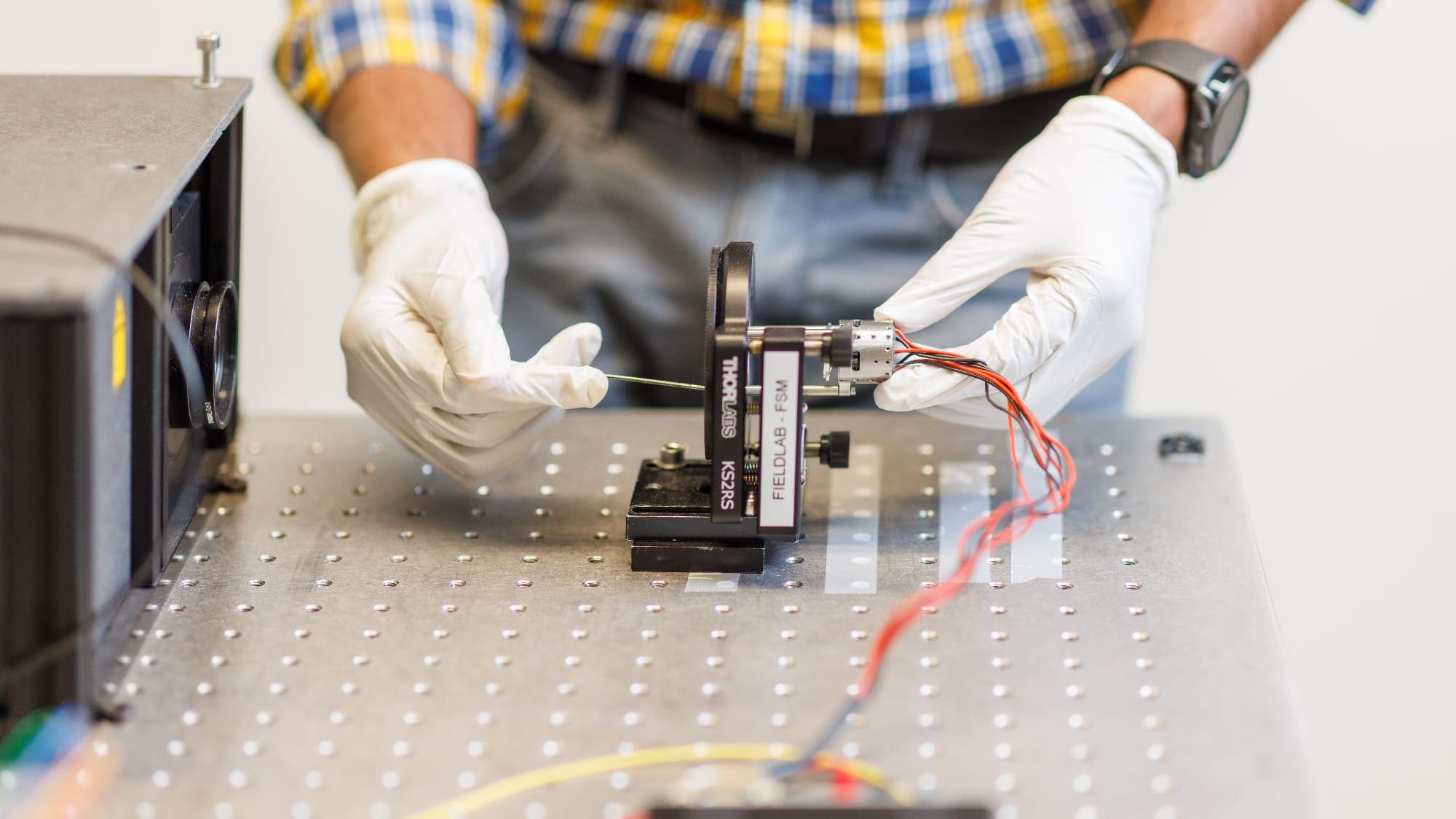

optical system assembly.

Demcon focal manufactures optical systems in small volumes up to 50-100 per year. We can assemble laser modules, optical lens systems, microscope system and optomechatronic systems, such as the fine steering mirror.

artificial intelligence.

Computation power is increasing rapidly and allows deep learning and neural network combinations for support tasks in recognition. Custom-made neural networks with proper data pre-processing will have a clear advantage over the more general neural networks without proper pre-processing. We design such custom-made inspection algorithms based on our concepts. In our concepts, the customer can create and train the network themselves without having knowledge of deep learning or neural networks. We also use synthetic data to train our neural networks. This helps to overcome the limited available training data set, and is useful when multiple defects need to be recognized.

surface measurements.

Surface measurements in sub-mm and sub-μm range for complex shape inspection tasks in industrial environment. Demcon focal has developed metrology systems that use different optical measurement principles, such as optical coherence topography, chromatic confocal methods, depth from shading, structured light, laser and led triangulation systems. These technologies are applied in height profile of MEMS chip structures, inline measurement in micro-machining systems, freeform lens measurement systems and surface irregularities inspection systems.